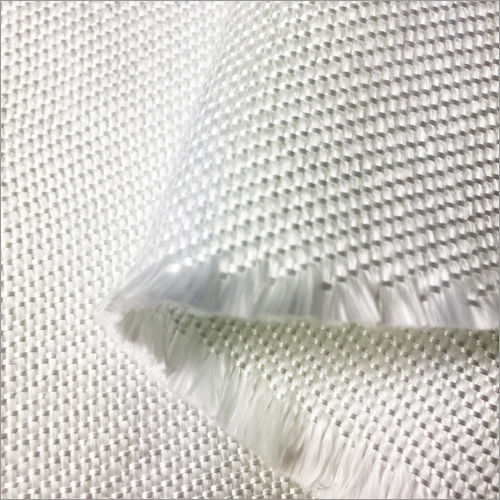

315g Woven Fiberglass Fabric

Product Details:

- Temperature Up to 550C continuous

- Coating Type Uncoated or silicon coated

- Thickness 0.28 mm (nominal)

- Density 2.55 Gram per cubic centimeter(g/cm3)

- Shape Roll

- Glass Type E-glass

- Thermal Conductivity Low thermal conductivity, approximately 0.038 W/mK

- Click to View more

315g Woven Fiberglass Fabric Price And Quantity

- 3.00 - 6.00 USD ($)/Square Meter

- 2000 , , Square Meter

315g Woven Fiberglass Fabric Product Specifications

- Customizable, e.g., 1m x 100m roll

- Woven

- Roll

- E-glass fiber

- 315 g/m

- Low thermal conductivity, approximately 0.038 W/mK

- Composites, fireproofing, marine, construction, automotive

- Silicon coated (optional), heat cleaned

- E-glass

- Uncoated or silicon coated

- Up to 550C continuous

- Insulation, heat protection, reinforcement material

- 2.55 Gram per cubic centimeter(g/cm3)

- 0.28 mm (nominal)

315g Woven Fiberglass Fabric Trade Information

- Shnaghai

- Letter of Credit (L/C), Telegraphic Transfer (T/T)

- 100000 , , Square Meter Per Month

- 30 Days

Product Description

315g Woven Fiberglass Fabric that brought forth by us is ideal to be utilized for a wide range of industrial applications such as fire blankets & curtains, heat shield, insulation cover, and so on. Featured with < 260 oC running temperature, 30-35 air permeability high tensile strength, 54x30 or 21x2 thread counts, and 1/3 twill woven pattern, it is made of the highest grade fiberglass thread with modern loom. In addition, 315g Woven Fiberglass Fabric can conveniently be availed from us in needed measures at affordable prices.

Specification :

- Product: 315g Woven Fiberglass Fabric

- Model: B-03

- Weave pattern: 1/3 Twill

- Weight: 315g

Product Details :

Thread Count | Weave Pattern | Weight | Air Permeability | Tensile Strength | Running Temperature | ||

No./Inch | No/cm | Wrap | Weft | ||||

54x30 | 21x12 | 1/3 Twill | 315+10 (G/m2) | 35-40 (CM3/CM2/S.127PA | >1400 (N/25mm) | >1000 (N/25mm) | <260oC |

Versatile Weave Patterns and Coatings

Choose between plain or twill weave patterns to suit the mechanical and aesthetic needs of your project. Optional silicon coating enhances the surface for improved abrasion and chemical resistance, while the uncoated version remains highly durable and heat tolerant. Heat-cleaned treatments ensure a clean and consistent product, optimizing performance in specialized applications.

Customizable Dimensions for Broad Applications

The fabric comes in a standard width of 1000 mm and can be cut to any length or produced in rolls (e.g., 1 m x 100 m) as required. Whether for construction, automotive, marine, or composite manufacturing, customizable sizing ensures seamless integration into your processes, reducing waste and maximizing efficiency.

FAQs of 315g Woven Fiberglass Fabric:

Q: How is the 315g woven fiberglass fabric used in insulation and heat protection?

A: This fabric is engineered from E-glass fibers that offer low thermal conductivity and high fire resistance, making it ideal for insulation and heat protection applications. It can be incorporated into building envelopes, equipment wraps, fireproof barriers, and automotive heat shields, withstanding temperatures up to 550C continuously.Q: What are the benefits of choosing a silicon coated option?

A: The silicon coating adds an extra layer of protection against chemicals, abrasion, and water penetration, while maintaining heat resistance. This treatment enhances durability and extends the products longevity in harsh environments, making it particularly suitable for marine, industrial, and outdoor uses.Q: In which industries can this fiberglass fabric be applied?

A: Given its excellent tensile strength, moisture resistance, and non-combustibility, the fabric is widely used in composites manufacturing, fireproofing, marine, construction, and automotive industries. Its customizable dimensions and robust performance make it versatile for various reinforcement and protection needs.Q: Can I request custom sizes or lengths for specific projects?

A: Yes, dimensions can be tailored according to your requirements. The standard width is 1000 mm, but you can specify the length or request special roll sizes (for example, 1 m x 100 m), ensuring a precise fit for your application and minimizing material waste.Q: What is the process for manufacturing this woven fiberglass fabric?

A: The fabric is produced by weaving E-glass fibers into either a plain or twill pattern. After weaving, it may undergo surface treatments such as heat cleaning for residue removal or silicon coating for enhanced properties, ensuring consistency and quality suited for advanced industrial use.Q: How does the materials fire resistance benefit my application?

A: The non-combustible nature of the E-glass fabric ensures that it will not support fire propagation, making it highly effective for applications where flame spread and safety are key concerns, such as fire barriers, protective linings, and components subject to heat exposure.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+