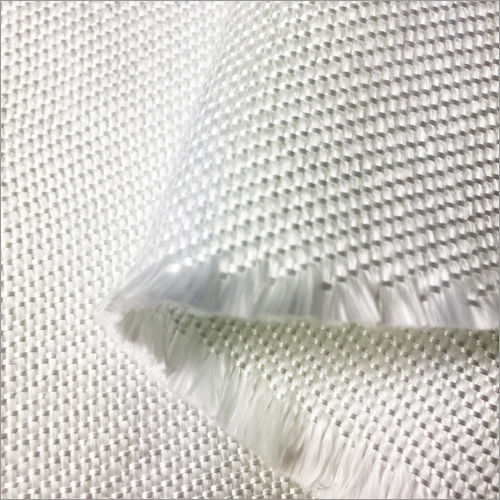

460g Woven Fiberglass Fabric

Product Details:

- Density 460 Gram per cubic centimeter(g/cm3)

- Glass Type E-glass

- GSM 460 gsm

- Usage & Applications Heat Protection, Electrical Insulation, Composite Lamination, Protective Clothing

- Temperature Up to 550C (uncoated) or as per coating

- Shape Roll, Sheet

- Thermal Conductivity Low, typically 0.035 W/(mK)

- Click to View more

460g Woven Fiberglass Fabric Price And Quantity

- 3.00 - 6.00 USD ($)/Square Meter

- 2000 , , Square Meter

460g Woven Fiberglass Fabric Product Specifications

- Roll, Sheet

- Industrial Insulation, Fireproofing, Reinforcement, Composite Molding, Marine, Automotive, Construction

- Woven

- Low, typically 0.035 W/(mK)

- Custom, e.g., 1M x 50M

- E-glass Fiberglass

- Silicone, PTFE, Acrylic, or Uncoated

- 0.40 mm

- Silicone Coated or Customized

- 460 gsm

- E-glass

- 460 Gram per cubic centimeter(g/cm3)

- Up to 550C (uncoated) or as per coating

- Heat Protection, Electrical Insulation, Composite Lamination, Protective Clothing

460g Woven Fiberglass Fabric Trade Information

- Shanghai

- Letter of Credit (L/C), Telegraphic Transfer (T/T)

- 100000 , , Square Meter Per Month

- 30 Days

Product Description

On account of our huge experience in textile industry, we are actively involved in proposed supreme 460g Woven Fiberglass Fabric. Featured with 1/3 twill woven pattern, < 260 oC running temperature, 30-35 air permeability and super tensile strength, it is ideal to use in crafting fire curtains, fire blankets, heat shields, welding curtains, stress relieving, expansion joints, flue ducts, removable insulation covers, etc. Furthermore, 460g Woven Fiberglass Fabric can easily be availed from us in required quantity at moderate prices.

Specification :

- Product: 460g Woven Fiberglass Fabric

- Model: B-02

- Weave pattern: 1/3 Twill

- Weight: 460g

Product Details :

Thread Count | Weave Pattern | Weight | Air Permeability | Tensile Strength | Running Temperature | ||

No./Inch | No/cm | Wrap | Weft | ||||

44x24 | 18x16 | 1/3 Twill | 460+10 (G/m2) | 33-35 (CM3/CM2/S.127PA | >2000 (N/25mm) | >1000 (N/25mm) | <260oC |

Versatile Applications Across Industries

Designed for use in industrial insulation, fireproofing, reinforcement, and composite molding, this 460g woven fiberglass fabric is a trusted solution in marine, automotive, and construction settings. Its high tensile and tear strength make it suitable for demanding applications, while its chemical resistance ensures long-term stability in harsh environments.

Superior Thermal and Mechanical Performance

With a density of 460 gsm and the ability to withstand temperatures up to 550C, this E-glass fabric provides outstanding protection against heat and flame. Its low thermal conductivity, non-combustible nature, and customizable surface treatmentssuch as silicone, PTFE, or acrylicmake it ideal for heat protection, electrical insulation, and protective clothing.

FAQs of 460g Woven Fiberglass Fabric:

Q: How is the 460g Woven Fiberglass Fabric typically used in industrial applications?

A: This fiberglass fabric is commonly used for insulation, fireproofing, composite lamination, and reinforcement in various industrial sectors, including construction, marine, and automotive. It delivers robust protection against heat, chemicals, and fire, making it suitable for environments where durability and safety are critical.Q: What are the benefits of choosing E-glass fiberglass for reinforcement and insulation?

A: E-glass fiberglass offers excellent strength-to-weight ratio, non-combustibility, and superior resistance to chemicals and mildew. Its low water absorption and thermal conductivity make it an ideal choice for reinforcing structures and providing effective insulation in high-temperature applications.Q: When should a silicone or PTFE surface treatment be selected for this fabric?

A: Silicone or PTFE coatings enhance the fabrics chemical and abrasion resistance, improve its ability to withstand higher temperatures, and add water- and oil-repellent properties. These treatments are recommended when additional protection or specific performance features are needed in your application.Q: Where should the 460g Fiberglass Fabric be stored to maintain its properties?

A: To preserve the fabrics integrity, it should be stored in a dry, cool place and protected from direct sunlight. This helps prevent degradation from moisture, mold, and UV exposure, ensuring long-lasting performance.Q: What is the standard process for customizing the roll dimensions or surface treatment?

A: Customers can specify desired roll length, width, and surface treatment (such as silicone, PTFE, or acrylic) when placing their order. The manufacturer accommodates customization requests based on application requirements and can supply fabric in roll, sheet, or other shapes as needed.Q: How does this fabric contribute to fire safety in construction and industrial settings?

A: With its non-combustible nature and ability to withstand temperatures up to 550C (uncoated), this fiberglass fabric acts as an effective fire barrier. It is used in fireproofing applications for walls, ceilings, and protective clothing to enhance safety in fire-prone environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+