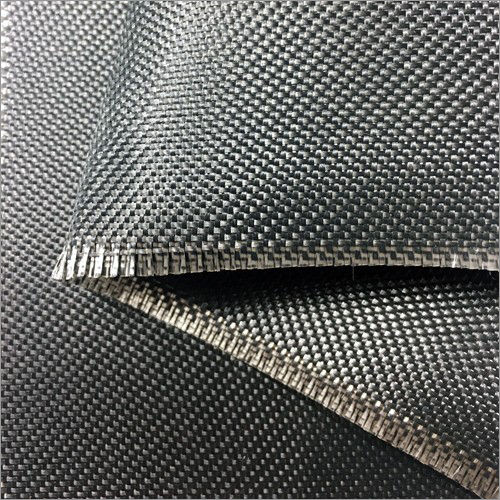

470g PTFE Graphite Silicone Finished Fabric

Product Details:

- Shape Roll / Sheet

- Glass Type E-glass

- Usage & Applications Suitable for non-stick, heat-resistant, anti-corrosive and chemical resistant surface applications

- Temperature -70C to +260C

- Thickness 0.43 mm

- GSM 470 GSM

- Density 470 Gram per cubic centimeter(g/cm3)

- Click to View more

470g PTFE Graphite Silicone Finished Fabric Price And Quantity

- 4.00 - 6.00 USD ($)/Square Meter

- 2000 , , Square Meter

470g PTFE Graphite Silicone Finished Fabric Product Specifications

- 470 GSM

- -70C to +260C

- 0.43 mm

- Suitable for non-stick, heat-resistant, anti-corrosive and chemical resistant surface applications

- E-glass

- Customizable, standard 1 m width, length as per requirement

- Roll / Sheet

- PTFE Graphite Silicone finished

- Fiberglass base with PTFE Graphite Silicone coating

- Low thermal conductivity

- Woven and impregnated with PTFE graphite silicone compound

- PTFE Graphite Silicone

- 470 Gram per cubic centimeter(g/cm3)

- Industrial insulation, heat sealing, gasket production, conveyor belts, electrical insulation

470g PTFE Graphite Silicone Finished Fabric Trade Information

- Shanghai

- 100000 , , Square Meter Per Month

- 30 Days

Product Description

470g PTFE Graphite Silicone Finished Fabric has high tensile strength, high temperature resistance, super fire resistance, and ability to enhance resistance to flame and abrasion. As a result, it has myriad usages in varied industrial places. It is made of 44x24 or 18x10 count thread with ultra-advanced weaving technology, ensuring its less air permeability, tear resistance, and 1/3 twill weave pattern. Moreover, clients can easily be approached us thorough this website to avail 470g PTFE Graphite Silicone Finished Fabric in needed amounts at moderate prices.

Specification :

- Product: 470g PTFE Graphite Silicone Finished Woven Fiberglass Fabric

- Model: B-02S

- Weave pattern: 1/3 Twill

- Finishing: PTFE Graphite Silicone Finished

- Weight: 470g

Product Details :

Thread Count | Weave Pattern | Weight | Air Permeability | Loss on logition | Tensile Strength | Mullen brust | Finish | Running Temperature | ||

No./Inch | No/cm | Wrap | Weft | |||||||

44x24 | 18x10 | 1/3 Twill | 470+15 (G/m2) | 15-30 | >3 (%) | >2000 (N/25mm) | >1000 (N/25mm) | >800 (psi) | PTFE Graphic Silicone Finish | <260oC |

Outstanding Multi-Purpose Performance

This PTFE Graphite Silicone Finished Fabric provides unmatched mechanical strength while maintaining flexibility and stability under high thermal stress. Its superior flame resistance, chemical repellency, and excellent tear strength make it suitable for a diverse range of demanding industrial applications.

Superior Surface and Environmental Endurance

The fabrics smooth, non-stick PTFE graphite silicone finish resists contamination and enables easy cleaning, boosting operational hygiene. Non-absorbent and impervious to most industrial chemicals, it ensures long-term service, even in corrosive or high-temperature environments from -70C up to +260C.

Flexible Supply and Customization

Available in standard 1000 mm wide rolls or custom sizes to meet specific requirements, the fabric is supplied polythene-wrapped and ready for export. Its consistent quality and compliance with strict fire and safety standards make it a reliable choice for manufacturers and distributors worldwide.

FAQs of 470g PTFE Graphite Silicone Finished Fabric:

Q: How is the PTFE Graphite Silicone Finished Fabric typically used in industrial applications?

A: This fabric is widely employed in insulation, heat sealing, gasket manufacture, conveyor belts, and electrical insulation. Its non-stick, heat-resistant, and anti-corrosive properties also make it suitable for applications requiring robust protection against harsh chemicals and high temperatures.Q: What benefits does the PTFE graphite silicone coating provide?

A: The PTFE graphite silicone coating imparts a smooth non-stick surface, significantly improves flame resistance, and provides excellent protection against acids, bases, and solvents. It also enhances the fabrics mechanical and chemical durability, supporting longer service life and easier maintenance.Q: When should I choose this material over other industrial fabrics?

A: Select this material when you require excellent flame resistance, high tensile and tear strength, and reliable chemical insulation in environments with exposure to extreme temperatures (-70C to +260C) or aggressive chemicals. Its low elongation and non-absorbent nature make it ideal for precision and safety-critical applications.Q: Where can this fabric be installed or applied?

A: This fabric is suitable for installation in industrial settings such as power plants, chemical processing facilities, thermal insulation systems, food processing lines, or anywhere requiring non-stick, heat-resistant, and durable surface protection.Q: What is the process of manufacturing this finished fabric?

A: The fabric is produced by weaving E-glass fiberglass, then impregnating and coating it with a PTFE graphite silicone compound. This combination provides superior physical, chemical, and thermal properties, resulting in a smooth and non-porous surface that meets industrial performance standards.Q: How does the product meet fire and safety compliance requirements?

A: It is engineered to be self-extinguishing and flame resistant, with properties that comply with industrial fire and safety standards. This ensures safe usage even in high-risk environments prone to heat and flame exposure.Q: What are the packaging and delivery options for this fabric?

A: The fabric is supplied in polythene-wrapped rolls, with a standard width of 1000 mm or customized as specified by the customer. Length and shape can be tailored to fit unique application needs, making it suitable for both small-scale installations and large industrial projects.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+