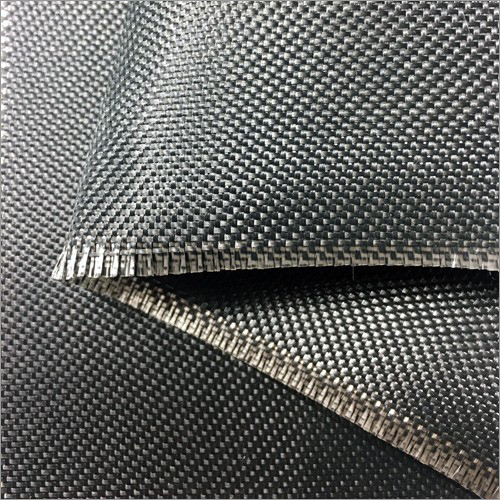

550g Woven Fiberglass Fabric With Graphite Finished

Product Details:

- Glass Type E-glass

- Density 550 Gram per cubic centimeter(g/cm3)

- Thickness 0.45 mm to 0.6 mm (typical range)

- Usage & Applications Heat insulation, flame barrier, safety clothing, industrial protection

- Coating Type Graphite

- Temperature Up to 750C continuous, short exposure up to 1000C

- Thermal Conductivity Low, designed for effective thermal insulation

- Click to View more

550g Woven Fiberglass Fabric With Graphite Finished Price And Quantity

- 4.00 - 6.00 USD ($)/Square Meter

- 2000 , , Square Meter

550g Woven Fiberglass Fabric With Graphite Finished Product Specifications

- Roll or sheet

- 550 GSM

- Woven

- Low, designed for effective thermal insulation

- E-glass fiberglass with graphite coating

- Customizable, typical roll width 1 meter

- E-glass

- Up to 750C continuous, short exposure up to 1000C

- Graphite Finished

- Graphite

- 0.45 mm to 0.6 mm (typical range)

- 550 Gram per cubic centimeter(g/cm3)

- High-temperature insulation, fire protection, welding blankets, heat shields

- Heat insulation, flame barrier, safety clothing, industrial protection

550g Woven Fiberglass Fabric With Graphite Finished Trade Information

- Shanghai

- 100000 , , Square Meter Per Month

- 30 Days

Product Description

550g Woven Fiberglass Fabric With Graphite Finishedhas high temperature resistance, super tensile strength, excellent flame resistance, and ability to increase resistance to abrasion and moisture. As a result, it has great usage in multiple industrial sectors. It is well crated from 54x48 or 19x21 count thread with sophisticated loom, guaranteeing its low air permeability, high tear resistance, and 2/5 satin weave pattern. Moreover, one can conveniently be reached us via this online portal to buy the550g Woven Fiberglass Fabric With Graphite Finishedin required quantity at competitive prices.

Product Specifications :

- Product: 550g Woven Fiberglass Fabric with Graphite Finished

- Model: B-15X

- Weave pattern: 2/5 Satin

- Finishing: Graphite Finished

- Weight: 550g

Product Details :

|

Thread Count |

Weave Pattern |

Weight |

Air Permeability |

Loss on logition |

Tensile Strength |

Mullen brust |

Finish |

Running Temperature |

||

|

No./Inch |

No/cm |

Wrap |

Weft |

|||||||

|

54x48 |

21x19 |

2/5 Stain |

550+15 (G/m2) |

30-50 |

>1.5 (%) |

>2000 (N/25mm) |

>2000 (N/25mm) |

>600 (psi) |

Graphite Finished |

<260oC |

Engineered for Heat and Flame Protection

Featuring a graphite finish over robust E-glass fibers, this woven fiberglass fabric stands out for its ability to withstand extreme heat and direct flame. The enhanced flame resistance makes it suitable for demanding environments such as welding zones, fire protection barriers, and industrial insulation. Its structural integrity is maintained even under short-term temperatures reaching up to 1000C.

Versatile and Customizable Industrial Applications

With standard roll dimensions of 1 meter width and 50 meters length, and options for customization, this fabric adapts easily for different needs. Whether used as a heat shield, welding blanket, or safety apparel, the materials high tensile strength, chemical resistance, and abrasion durability ensure long-term reliability in tough settings.

FAQs of 550g Woven Fiberglass Fabric With Graphite Finished:

Q: How is the 550g Woven Fiberglass Fabric with Graphite Finish typically used?

A: This fabric is primarily used for high-temperature insulation, welding blankets, fire protection barriers, heat shields, and industrial safety clothing. Its strong heat and flame resistance make it suitable for environments exposed to intense heat or potential fire hazards.Q: What benefits does the graphite finish provide?

A: The graphite coating significantly enhances the fabrics abrasion resistance, moisture resistance, and flame retardancy. It also contributes to the fabrics non-combustibility, making it ideal for applications requiring fire safety and longevity.Q: When should this fabric be chosen over standard fiberglass fabrics?

A: Opt for this graphite-finished fabric when you need superior flame resistance, enhanced abrasion protection, and excellent moisture and chemical resistance. It is especially recommended for applications where exposure to acids, alkalis, or intermittent extreme heat is expected.Q: Where is this fabric typically installed or applied?

A: This material is widely used in industrial settings, such as manufacturing plants, welding stations, power generation facilities, and construction sites. It serves as insulation in machinery, flame barriers in workspaces, and protective coverings on surfaces exposed to high temperatures.Q: What process is used to achieve the graphite finish on the fabric?

A: After weaving E-glass fiberglass into plain or twill patterns, a graphite-based coating is applied. This finish enhances the materials heat, moisture, and abrasive resistance, preparing it for high-performance industrial applications.Q: How customizable are the widths and lengths of this fiberglass fabric?

A: While the standard roll measures 1,000 mm in width and 50 meters in length, both dimensions can be tailored to meet specific requirements. Custom thicknesses (typically 0.45 mm to 0.6 mm) are also available to suit various project needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+