470g Acid-Resistant Finished Woven Fabric

Product Details:

- Usage & Applications Protective clothing, filtration, reinforcement, sealing material

- Density 470 Gram per cubic centimeter(g/cm3)

- Glass Type E-glass

- Thermal Conductivity Low, suitable for thermal insulation applications

- GSM 470 GSM

- Temperature Working up to 550C

- Coating Type Acid-resistant chemical coating

- Click to View more

470g Acid-Resistant Finished Woven Fabric Price And Quantity

- 2000 , , Square Meter

- 4.00 - 6.00 USD ($)/Square Meter

470g Acid-Resistant Finished Woven Fabric Product Specifications

- Woven

- Rolls or cut sheets

- 0.43 mm

- Glass fiber

- 470 Gram per cubic centimeter(g/cm3)

- Protective clothing, filtration, reinforcement, sealing material

- Working up to 550C

- Customizable (standard width: 1-2 meters, length as per requirement)

- Acid-resistant chemical coating

- 470 GSM

- Low, suitable for thermal insulation applications

- Acid-resistant finished

- E-glass

- Industrial protection, chemical filtration, acid-resistant barriers

470g Acid-Resistant Finished Woven Fabric Trade Information

- Shanghai

- Letter of Credit (L/C), Telegraphic Transfer (T/T)

- 100000 , , Square Meter Per Month

- 30 Days

Product Description

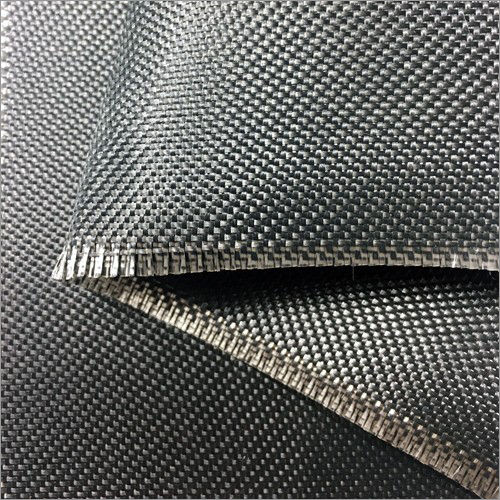

Being the foremost firm in textile industry, we are dedicated towards proposing supreme 470g Acid-Resistant Finished Woven Fabric. Featured with 1/3 twill weave pattern, great tensile strength and low air permeability, such kind of fabric is most commonly used for making welding curtains, heat shields, stress relieving, fire blankets, fire curtains, insulation covers, flue ducts, expansion joints, etc. Besides, 470g Acid-Resistant Finished Woven Fabric has embossed pattern, smooth texture, and can be purchased from us through this website at economical prices.

Product Specification :

- Product: 470g Acid-Resistant Finished Woven Fiberglass Fabric

- Model: B-02N

- Weave pattern: 1/3 Twill

- Finishing: Acid-Resistant Finished

- Weight: 470g

Product Details :

Thread Count | Weave Pattern | Weight | Air Permeability | Loss on logition | Tensile Strength | Mullen brust | Finish | Running Temperature | ||

No./Inch | No/cm | Wrap | Weft | |||||||

44x24 | 18x10 | 1/3 Twill | 500+15 (G/m2) | 15-30 | >10 (%) | >2000 (N/25mm) | >1200 (N/25mm) | >600 (psi) | Acid-resistant Finished | <260oC |

Durable and Versatile Industrial Fabric

This woven fabric is meticulously crafted for industrial applications requiring resistance to acids, high temperatures, and physical wear. Its low moisture absorption and robust tensile strength make it a versatile solution for industries where chemical exposure and thermal insulation are key concerns.

Customizable for Unique Specifications

With options for various weave patterns, colors, edge treatments, and packaging, this fabric can be tailored to precise requirements. Customers can request standard or fully customized dimensions, helping meet unique operational and installation needs.

Designed for Safety and Performance

Manufactured using E-glass fiber and advanced coating techniques, this fabric offers reliable protection in hazardous settings. It endures high temperatures, is non-flammable, and works effectively as a filtration, reinforcement, or sealing material across multiple industries.

FAQs of 470g Acid-Resistant Finished Woven Fabric:

Q: How is the acid-resistant woven fabric used in industrial applications?

A: The fabric is primarily used as a protective barrier against corrosive chemicals, as a filtration medium in chemical processing, and for thermal insulation. Its resistance to acids and high temperatures makes it suitable for protective clothing, reinforcement, and sealing purposes in various industries.Q: What makes this fabric suitable for high-stress and high-temperature environments?

A: Made from strong E-glass fiber and finished with an acid-resistant chemical coating, this fabric maintains high tensile strength and integrity even under significant mechanical stress or sustained heat, tolerating temperatures up to 550C.Q: When should I choose customized edge sealing or weave patterns?

A: Customized edge sealing is recommended when enhanced durability or resistance to fraying is needed, especially in repetitive handling or abrasive environments. Custom weave patterns can be selected to meet specific filtration or strength requirements for unique applications.Q: Where can this acid-resistant fabric be installed or applied?

A: It is suitable for use in chemical plants, manufacturing facilities, and environments where acid exposure, moisture, and heat are concerns. Typical installations include filtration units, protective barriers, thermal insulation layers, and reinforcement in equipment or structures.Q: What is the process for ordering this product with custom specifications?

A: Simply specify your required color, weave pattern, dimensions, edge treatment, and packing options when ordering. The manufacturer will process your requirements and provide the fabric in rolls or cut sheets, packed as per your instructions.Q: What are the main benefits of using this acid-resistant woven fabric?

A: Key benefits include high resistance to acids, excellent strength under stress, non-flammability, minimal moisture absorption, good abrasion resistance, and suitability for demanding industrial conditions, ensuring long-term performance and safety.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+