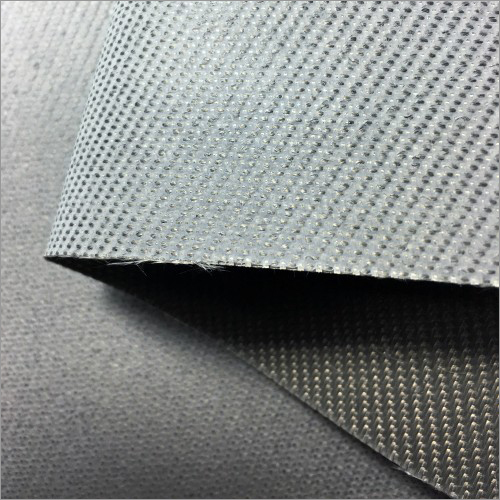

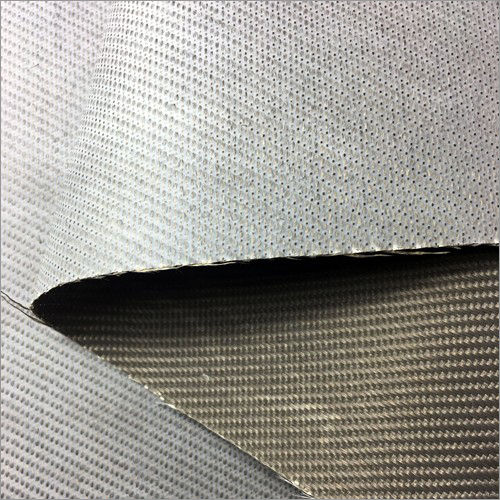

500g Fiberglass Fabric with Acid Resistant Finished and E-PTFE Membrane

Product Details:

- Thermal Conductivity Low

- Shape Roll / Sheet

- Density 500 Gram per cubic centimeter(g/cm3)

- Coating Type Acid Resistant + E-PTFE Membrane

- Temperature Continuous Use up to 260C

- Thickness 0.5 mm (nominal)

- Glass Type E-glass

- Click to View more

500g Fiberglass Fabric with Acid Resistant Finished and E-PTFE Membrane Price And Quantity

- 2000 , , Square Meter

- 4.00 - 6.00 USD ($)/Square Meter

- 1000 mm / 1200 mm / Custom

- White

- Outstanding

- Yes

- Excellent (due to microporous PTFE)

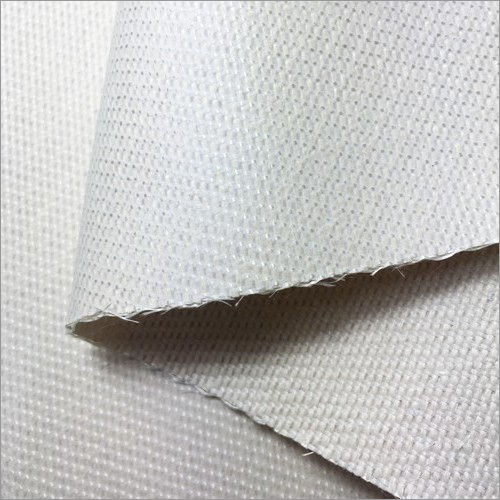

- Plain Weave

- High

- 50 m / Custom

- Anticorrosive, High Chemical Stability, Waterproof Membrane, Lightweight

- Good

- Low

- Strong Acid and Alkali Resistance

500g Fiberglass Fabric with Acid Resistant Finished and E-PTFE Membrane Product Specifications

- 500 Gram per cubic centimeter(g/cm3)

- Acid Resistant + E-PTFE Membrane

- Low

- Roll / Sheet

- Customizable

- Woven

- Continuous Use up to 260C

- Filter Cloth, Acid Filtration, Chemical Resistant Barriers, Heat Shielding, High Temperature Ventilation

- 500 GSM

- Industrial Filtration, Acid Gas Filtration, High Performance Chemical Fabrics, Pollution Control

- Acid Resistant Finish + E-PTFE Membrane Lamination

- E-glass Fiberglass with E-PTFE Membrane

- E-glass

- 0.5 mm (nominal)

- 1000 mm / 1200 mm / Custom

- White

- Outstanding

- Yes

- Excellent (due to microporous PTFE)

- Plain Weave

- High

- 50 m / Custom

- Anticorrosive, High Chemical Stability, Waterproof Membrane, Lightweight

- Good

- Low

- Strong Acid and Alkali Resistance

500g Fiberglass Fabric with Acid Resistant Finished and E-PTFE Membrane Trade Information

- Shanghai

- Letter of Credit (L/C), Telegraphic Transfer (T/T)

- 100000 , , Square Meter Per Month

- 30 Days

Product Description

500g Fiberglass Fabric with Acid Resistant Finished and E-PTFE Membrane has super flame resistance, high tensile strength, excellent running temperature resistance, and ability to enhance resistance to abrasion. Hence, it has use in various industrial applications. The proposed fabric is manufactured from supreme fiberglass thread with technically advanced loom that ensure its less air permeability, 1/3 weave pattern and long life. Besides, 500g Fiberglass Fabric with Acid Resistant Finished and E-PTFE Membrane can be availed in desired measurements at compromising prices.

Product Details :

- Product: 500g Fiberglass Fabric with Acid Resistant Finished and E-PTFE Membrane

- Model: B-02NF

- Weave pattern: 1/3 Twill

- Finishing: Acid Resistant Finished

- Weight: 500gsm

Product Specification :

Thread Count | Weave Pattern | Weight | Air Permeability | Loss on logition | Tensile Strength | Mullen brust | Finish | Running Temperature | ||

No./Inch | No/cm | Wrap | Weft | |||||||

44x24 | 18x10 | 1/3 Twill | 500+15 (G/m2) | 2-5 | >10 (%) | >2000 (N/25mm) | >1200 (N/25mm) | >600 (psi) | Acid-resistant Finished+membrane | <260oC |

Versatile High-Performance Industrial Fabric

Engineered for durability and reliability, the 500g fiberglass fabric with acid-resistant, E-PTFE membrane lamination delivers multifaceted protection in challenging environments. Its advanced construction makes it suitable for filter cloth, acid filtration, heat shielding, and high-temperature ventilation. Lightweight yet structurally robust, it meets the demands of industries requiring both flexibility and strength, offering users confidence in performance across various chemical and thermal exposures.

Customizable Solutions for Industrial Needs

To address diverse application requirements, this fabric is offered in customizable widths, lengths, and shapes. With options for OEM manufacturing, businesses can specify dimensions and thickness to align with their production needs. Its exceptional adaptability, reinforced by strong PH resistance and thermal stability, ensures a precise fit for unique projects, making it an optimal choice for distributors, manufacturers, and end-users alike.

FAQs of 500g Fiberglass Fabric with Acid Resistant Finished and E-PTFE Membrane:

Q: How does the acid-resistant finish and E-PTFE membrane enhance the fabrics performance?

A: The acid-resistant finish protects the fiberglass from corrosive chemicals, while the E-PTFE membrane adds an extra layer of chemical stability and impermeability. This combination enables the fabric to maintain integrity and function even when exposed to harsh acids or alkalis, providing long-term durability in demanding industrial environments.Q: What are the main applications of this fiberglass fabric?

A: This fabric is primarily used for filter cloth, acid gas filtration, chemical resistant barriers, heat shielding, and high temperature ventilation. Its high chemical resistance and thermal stability make it suitable for use in industries such as chemical processing, pollution control, and high-performance industrial manufacturing.Q: When should this fabric be selected over other filtration or barrier materials?

A: Choose this fabric when your application requires robust resistance to acids, alkalis, and high temperatures up to 260C. Its superior tensile strength, excellent air permeability, and outstanding water repellency make it an ideal option for environments where chemical exposure and extreme conditions are prevalent.Q: Where is the product commonly supplied or exported from?

A: This fiberglass fabric is manufactured and exported primarily from China, and is available through distributors, exporters, manufacturers, suppliers, and traders with global reach. Its customizable options support diverse industrial requirements worldwide.Q: What is the process for ordering custom dimensions or OEM solutions?

A: To order custom dimensions or OEM versions, you can specify your required width, length, thickness, and membrane properties directly to the supplier or manufacturer. They will tailor the production process to meet your exact specifications, ensuring a solution that fits your technical and operational needs.Q: How is the fabric typically used in industrial settings?

A: In industrial settings, the fabric is commonly integrated into filtration systems, used as a barrier material to contain or separate chemicals, or employed as a protective heat shield. Its high flexibility and resilience allow for installation as both sheets and rolls, adapting easily to equipment or facility requirements.Q: What are the benefits of using this particular fiberglass fabric in chemical filtration systems?

A: This fabric provides high chemical resistance, excellent air permeability due to the microporous E-PTFE membrane, and outstanding durability under acidic and alkaline conditions. These benefits result in efficient filtration, extended lifespan, and reduced maintenance costs, making it highly cost-effective for chemical filtration operations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+