750g Fiberglass Fabric With PTFE Finished and E-PTFE Membrane

Product Details:

- Thickness 0.7mm - 1.0mm

- Coating Type PTFE Coating with laminated E-PTFE Membrane

- GSM 750 GSM

- Glass Type E-glass

- Density 750 Gram per cubic centimeter(g/cm3)

- Shape Roll, Sheet

- Usage & Applications Filter Media, High-Temperature Gas Filtration, Chemical Resistant Fabrics

- Click to View more

750g Fiberglass Fabric With PTFE Finished and E-PTFE Membrane Price And Quantity

- 2000 , , Square Meter

750g Fiberglass Fabric With PTFE Finished and E-PTFE Membrane Product Specifications

- Continuous Use Up to 260C

- Woven Fabric With PTFE Coating

- 750 Gram per cubic centimeter(g/cm3)

- Roll, Sheet

- Industrial Filtration, Chemical Processing, High-Temperature Insulation, Dust Collection Systems

- Low, suitable for thermal insulation

- E-Glass Fiberglass with PTFE and E-PTFE Membrane

- Filter Media, High-Temperature Gas Filtration, Chemical Resistant Fabrics

- 750 GSM

- PTFE Finished with E-PTFE Membrane

- PTFE Coating with laminated E-PTFE Membrane

- E-glass

- Customizable; Standard Width: 1000mm - 1500mm

- 0.7mm - 1.0mm

750g Fiberglass Fabric With PTFE Finished and E-PTFE Membrane Trade Information

- Shanghai

- Letter of Credit (L/C), Telegraphic Transfer (T/T)

- 100000 , , Square Meter Per Month

- 30 Days

Product Description

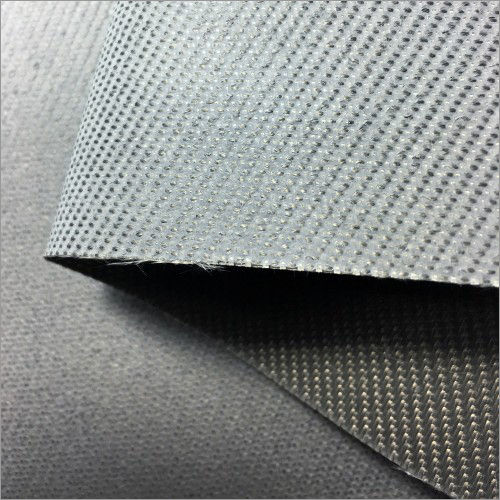

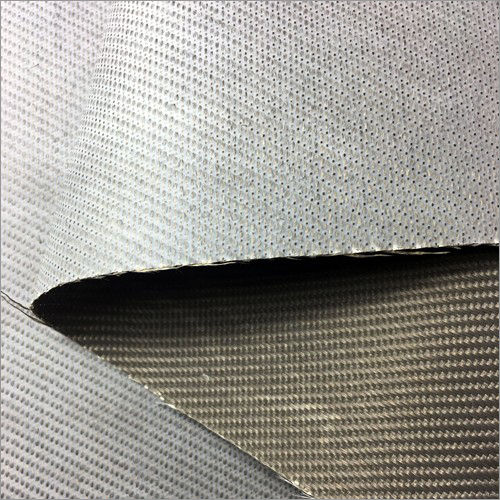

750g Fiberglass Fabric With PTFE Finished and E-PTFE Membranethat we are presenting has dual twill weave pattern that ensure low air permeability, super tensile strength, good temperature resistance, and excellent insulation. Suitable for welding curtain, fire curtain, fire blanket, heat shield and many other industrial applications, this type of fabric is crafted from ideal thickness thread with technically advanced loom, guaranteeing its long life. Clients can buy the750g Fiberglass Fabric With PTFE Finished and E-PTFE Membranein needed amounts at reasonable prices.

Product Specifications :

- Product: 750g Fiberglass Fabric with PTFE Finished and E-PTFE Membrane

- Model: B-01PF

- Weave pattern: Double Twill

- Finishing: PTFE Finished

- Weight: 750gsm

Product Details :

|

Thread Count |

Weave Pattern |

Weight |

Air Permeability |

Loss on logition |

Tensile Strength |

Mullen brust |

Finish |

Running Temperature |

||

|

No./Inch |

No/cm |

Wrap |

Weft |

|||||||

|

48x40 |

19x16 |

Double Twill |

750+25 (G/m2) |

2-5 |

>10 (%) |

>2400 (N/25mm) |

>2000 (N/25mm) |

>800 (psi) |

PTFE Finish + membrane |

<260oC |

High Tensile Strength for Heavy-Duty Operations

This fiberglass fabric excels in demanding environments, thanks to an E-glass base imparting significant tensile strength. The robust construction is ideal for industrial filtration, chemical processing, and high-temperature insulation, ensuring reliable performance and operational safety under heavy load conditions.

Advanced PTFE and E-PTFE Membrane Technology

Combining PTFE finish with a microporous E-PTFE membrane, the fabric offers controlled air permeability and outstanding water repellency. The technology delivers an easy-clean, anti-stick surface and enhances filtration efficiency, making it suitable for precise industrial and chemical filtering applications.

Exceptional Resistance and Safety Features

Built to withstand acids, bases, and industrial solvents, the fabric is highly chemically resistant. Its flame-retardant nature and RoHS/REACH compliance further boost safety credentials, making it a reliable choice in hazardous and regulated environments.

FAQs of 750g Fiberglass Fabric With PTFE Finished and E-PTFE Membrane:

Q: How is the 750g Fiberglass Fabric with PTFE Finish and E-PTFE Membrane used in industrial filtration?

A: It serves as a high-efficiency filter media in dust collection systems and high-temperature gas filtration, thanks to its microporous E-PTFE membrane and customizable air permeability. The materials durability supports prolonged and rigorous filtration processes.Q: What benefits does the PTFE finish provide to this fabric?

A: The PTFE finish ensures excellent water repellency and a smooth, anti-stick surface. This facilitates easy cleaning and maintenance while enhancing the fabrics resistance to stains and corrosion in harsh industrial environments.Q: When is it recommended to use this fabric for chemical processing applications?

A: This fabric is ideal when exposure to aggressive chemicals such as acids, bases, and solvents is expected. Its exceptional chemical resistance and strong adhesion between layers protect against degradation and prolong service life.Q: Where can I customize the dimensions and air permeability of this fiberglass fabric?

A: Customization options including width, thickness, and air permeability are available directly from distributors, manufacturers, or suppliers. Standard widths range from 1000mm to 1500mm to fit diverse operational needs.Q: What process is used to manufacture the fiberglass fabric with PTFE coating and E-PTFE membrane?

A: The material is produced by weaving E-glass fiberglass, then applying a PTFE coating followed by laminating an E-PTFE membrane. This process ensures strong adhesion and integrates enhanced filtration and surface properties.Q: How does the fabric provide environmental compliance and safety?

A: The product meets RoHS and REACH specifications, confirming minimal hazardous substance usage. Its flame-retardant and thermal insulation capabilities make it safe for use in regulated, temperature-critical settings.Q: What are the main applications and usage scenarios for this product?

A: Key applications include industrial filtration, chemical processing, high-temperature insulation, and use as chemical-resistant fabrics. It operates efficiently up to 260C and is available in roll or sheet forms for diverse installation requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+